- Best Practices New Normal

- Digital Dentistry

- Data Security

- Implants

- Catapult Education

- COVID-19

- Digital Imaging

- Laser Dentistry

- Restorative Dentistry

- Cosmetic Dentistry

- Periodontics

- Oral Care

- Evaluating Dental Materials

- Cement and Adhesives

- Equipment & Supplies

- Ergonomics

- Products

- Dentures

- Infection Control

- Orthodontics

- Technology

- Techniques

- Materials

- Emerging Research

- Pediatric Dentistry

- Endodontics

- Oral-Systemic Health

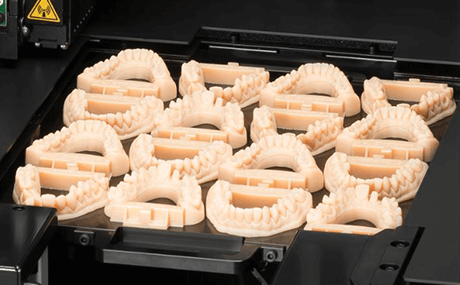

Weekly Tech: 3D Printers

Technology is quickly transforming dentistry. From digital record-keeping to machines that seem straight out of a SciFi feature, the 21st century has gifted the medical industry some amazing devices. Dentists are especially proactive about adopting new technology in their practices, so DMD is bringing you a weekly spotlight on some of the best products on the market. Continue below to read about this week's focus, 3D printers.

3D printers can be used across multiple dental specialties, according to our tech columnist.

Whether it’s in the lab or in your practice, 3D printers are streamlining dental workflow.

3D printers use additive manufacturing techniques to construct a variety of dental models layer by layer. As a result, dental laboratories have incorporated these systems into their regular workflow. Some dentists have also taken the initiative to purchase 3D printers for their own offices.

RELATED:

- The 7 Things Patients Want in a Dentist

- Stay Ahead of The Curve by Improving Geriatric Patient Care

- 50 Ways I'd Like to Enjoy Early Retirement

“By combining oral scanning, CAD/CAM design and 3D printing, dental labs can accurately and rapidly produce crowns, bridges, stone models and a range of orthodontic appliances,” writes 3D printer supplier Javelin-Tech.

Restorations and Molds

The traditional approach to restorations and molds can be long and arduous. Now, 3D printers allow dentists and dental labs to dramatically cut down on the process by using digital scans to computationally fit and print dental restorations.

“It normally took about five to seven days to produce a restoration,” said Don Albensi, D.D.T., owner and founder of Albensi Dental Laboratory. “We’ve developed it now to a digital workflow that we can create restorations within two to three days.”

A dentist can capture a digital rendering of a restoration site using a chairside oral scanner (COS) and email it to a dental lab. The lab uses computational software to generate a 3D digital replica of the site. They then use the same system to design a restoration with adequate margins and detail. A 3D printer analyses the file and prints the final restoration or model and die overnight.

Albensi Dental laboratory uses the Stratasys Ltd Object series dental line. Check out these printers here.

Surgical Guides

Guided implant surgery requires expert treatment planning and accurate surgical guides. 3D printers and scanners are now an integral part of this process. Surgeons first create a digital model of the implant site by merging a digital scan of the area with a DICOM file from a cone beam scan. They can then use the digital renderings to create a detailed treatment plan and digital surgical guide model.

“It is fast and easy to plot the location and borders of the guide. Once the plot is selected and all involved areas are considered, the software virtually generates a hole where the drill guide sleeve can be attached,” wrote Stratasys Ltd, leading dental 3D printer manufacturer.

After completing treatment planning, a surgeon can print the surgical guide using biocompatible material in their own office. Surgical guide vendors can also print the guide and deliver it to the clinician.

Orthodontics

The cost of storing and maintaining traditional plaster molds is a major contributor to overhead at orthodontic practices. Digital scanners and 3D printers can greatly reduce this cost and allow orthodontists to store digital models on a secure software based system rather than at a physical storage facility.

“Digital study models offer a reliable alternative to traditional plaster models. Their advantages in orthodontic diagnosis and treatment planning include easy and fast electronic transfer of data, immediate access and reduced storage requirement,” said Emilia Taveca in Intech.

Digital models can be sent to a lab for immediate printing of orthodontic appliances such as molds and retainers. Learn more about digitizing the orthodontic workflow here.

America's ToothFairy Initiative Bridges Dental Care Gap for Vulnerable Children

April 18th 2024America's ToothFairy, a nonprofit organization, aids safety-net dental clinics in providing essential care to children in need, with their recent online auction raising money to support access to dental services for thousands of vulnerable kids.